Carbon capture and utilization is a process that leads to the reduction of CO2 emissions, mainly from industrial sources, into the environment. The CO2 is removed from flue gas generated primarily from the combustion of fossil fuels using a variety of technologies, including chemical absorption, physical adsorption, or membrane processes. Carbon dioxide may be transformed into high-value products as: green methanol through reaction with green H2, fertilizers, polymers, construction materials.

CO2 CAPTURE TECHNOLOGY

is crucial for reducing

industrial carbon footprint

Moreover, CO2 can serve as an effective resource for Enhanced Oil Recovery (EOR) to increase the amount of extracted crude oil.

However, if it is uneconomical or impossible to use CO2 for other purposes to avoid negative environmental impacts, CO2 may be stored underground by injecting CO2 into extinct oil or gas fields.

A few synthesis technologies have reached commercial application (synthesis of urea, methanol, cyclic carbonates and salicylic acid), while others are under study to move from the demonstration stage to the commercial (inorganic carbonates, formic acid and polycarbonate-ether synthesis).

Modular Carbon Capture Solution

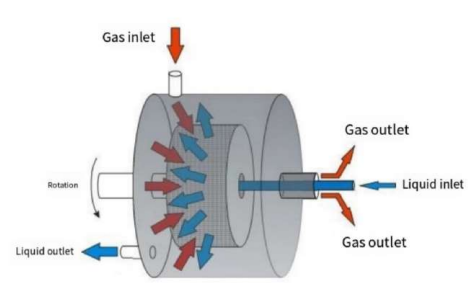

Rotating packed beds use centrifugal force to improve gas-liquid mass transfer, significantly reducing the height of the mass transfer unit compared to traditional tower beds. The technology, also known as supergravity technology, is revolutionizing transfer and reaction processes in the chemical industry. Using centrifugal force, the liquid flows outward through the bed. The high-speed rotation of the annular rotator further dilutes the gas-liquid layer, reducing mass transfer resistance and increasing equipment performance and processing capacity.

Rotating packet bed design

The modular carbon capture unit based on rotary packed bed technology can offer a compact solution with its smaller size, it can be modularly assembled in factories and transported in skid-mounted configurations, reducing on-site installation time, cost and minimizing disruption to existing production processes for customers.

Modular Carbon Capture SIEBC design

Offering Carbon Capture Technology Portfolio

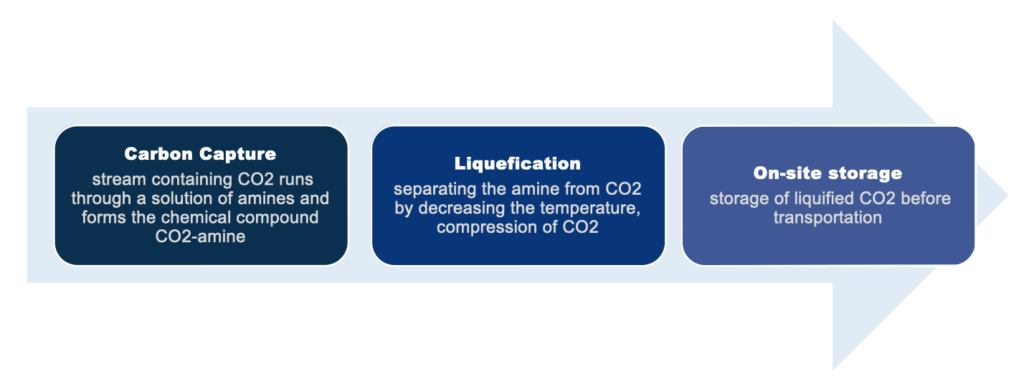

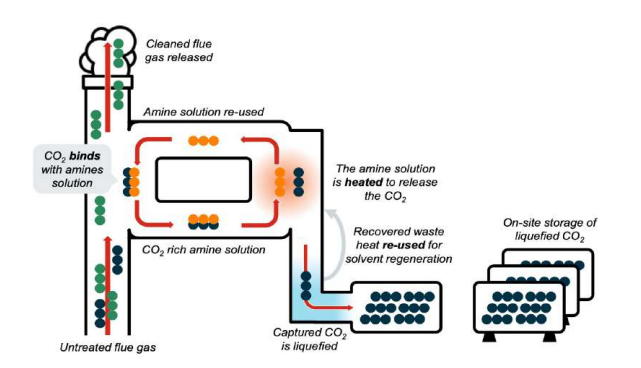

Process Stages:

Characteristics:

Minimum emissions

Non-toxic

Biodegradable

Minimum liquid waste and corrosion

Scheme of Carbon Capture Technology.