In pursuit of environmental responsibility, there is and ongoing effort to develop cleaner transportation technologies aimed at reducing the pollutants released into our atmosphere by hydrogen-powered systems integration. By reducing dependency on fossil fuels, we´re decreasing carbon footprint.

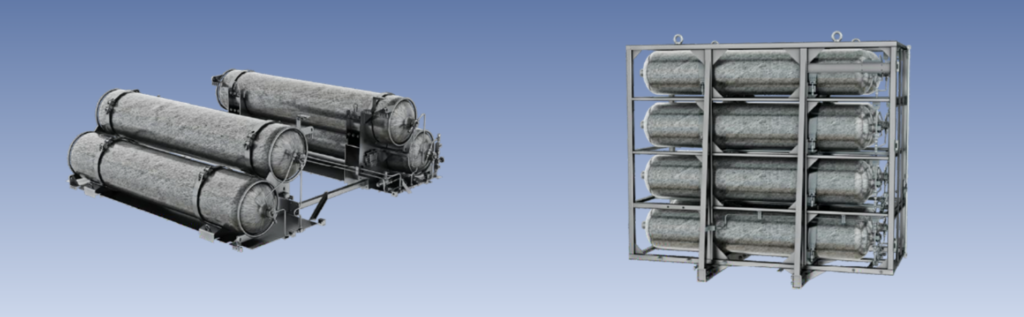

Our equipment includes advanced hydrogen supply system that stores and delivers hydrogen gas to the fuel cells, which generate electricity with zero emissions.

Utilizing advanced materials and innovative engineering techniques, the hydrogen supply system establish new standards for efficiency and safety.

Our advanced liquid hydrogen storage solution, with the highest hydrogen storage density (≥10%wt) involves a double-layer jacket structure and austenitic stainless steel construction. Storage bottles are designed to operate in the demanding liquid hydrogen temperature (-253°C), thanks to the special multi-layer insulation structure and laser welding technology. With a focus on durability and safety, our system is engineered to withstand high impact loads in heavy-duty truck applications.

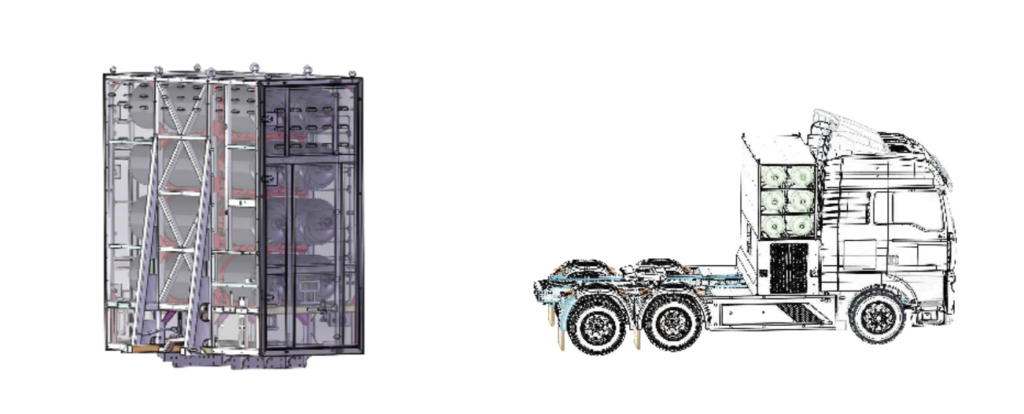

The vehicle’s hydrogen supply system powers the fuels cell engine and consists of two components:

Process system

Control system

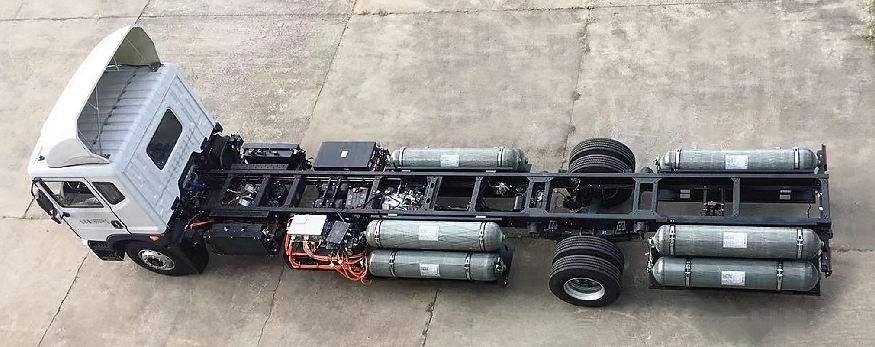

Process system includes hydrogen storage bottle with carbon fiber-wound aluminum-liner hydrogen storage bottle , a combined bottle valve, a relief valve, pressure regulator and pressure/temperature sensor.

The HSC01 hydrogen controller provides comprehensive monitoring and control functionalities for a reliable on-board hydrogen supply. It includes a real-time operating system that integrates various functions like valve control, temperature monitoring, hydrogen concentration measurement, pressure sensing, and CAN communication into one system for safety and reliability.

8x210L VHSS side-mounted on the logistics vehicle chassis