Alkaline electrolysis is recognized as one of the most advanced and widely adopted technologies for hydrogen production. In this method, two electrodes are immersed in an alkaline electrolyte solution- KOH, which enables the conduction of OH- anions.

Advantages

- Low operational cost due to usage of non-noble materials as catalysts

- Relatively high production efficiency

- Large-scale capability

- Effectively integrated with renewable energy

- Low investments costs

| TECHNICAL DESCRIPTION | Unit | CGA200 | CGA500 | CGA1000 | CGA2000 |

|---|---|---|---|---|---|

| Hydrogen production | NmZ/h | 200 | 500 | 1000 | 2000 |

| Operation pressure | MPa | 1.6(3.2) | 1.6 | 1.6 | * |

| Operating temperature | °C | 85~92 | 85~92 | 85~92 | * |

| Rated current | A(DC) | 3500 | 7000 | 14000 | * |

| DC Power consumption (BOL) | KWh/(Nm3H2) | 4.0~4.3 | 4.1~4.4 | 4.1~4.4 | * |

| DI Water consumption | L/h | ≤180 | ≤450 | ≤900 | * |

| KOH electrolyte concentrations | wt% | 30 | 30 | 30 | * |

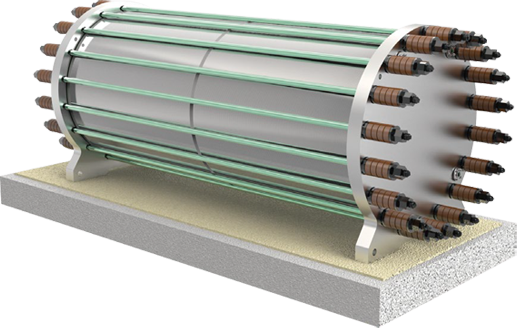

| Structural type of electrolyzer | – | Bipolar press filter | Bipolar press filter | Bipolar press filter | * |

| Polar plate | – | Carbon steel nickel plating | Carbon steel nickel plating | Carbon steel nickel plating | * |

| Anode/cathode material | – | nickel | nickel | nickel | * |

| Diaphragm material | – | PPS (asbestos free) | PPS (asbestos free) | PPS (asbestos free) | * |

| Electrolyzer weight | KG | 14700 | 35200 | 50000 | * |

| Dimensions of electrolyzer | mm | 3200*1649*1639 | 4200*2440*2555 | 6900*2440*2355 | * |

* DEVELOPMENT UNDER R+D